Service/Technical Information

SERVICE

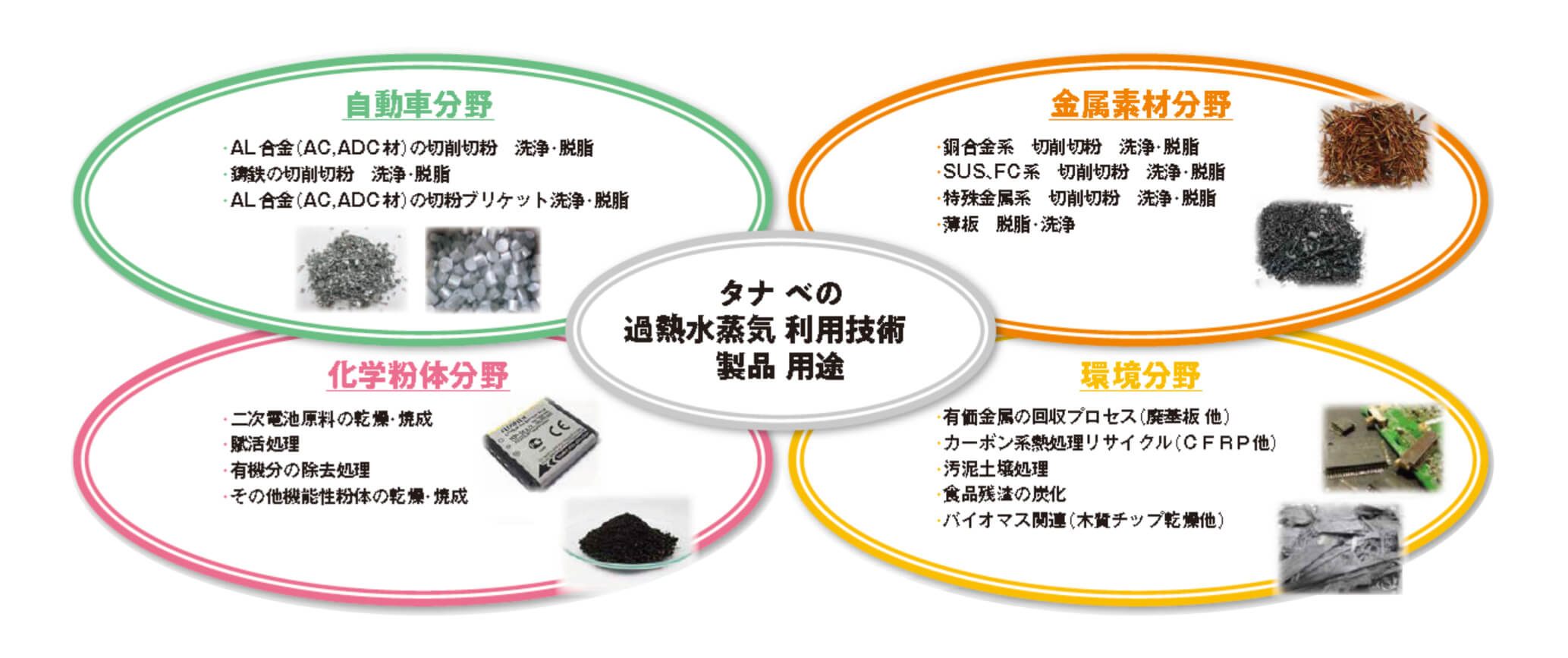

Superheated steam generated by adding heat to saturated steam. It has high energy density and thermal efficiency and is used in many industrial processes, power plants, etc.

Superheated steam (Kanetsu suijoki, English: super heated steam, abbreviation: SHS) is one of the states of steam. ) is gas. Generally, in the process of heating water and changing it to steam, when the steam reaches a saturated state, it becomes superheated steam by adding more heat. Superheated steam has high energy density and thermal efficiency and is used in many industrial processes and power plants.

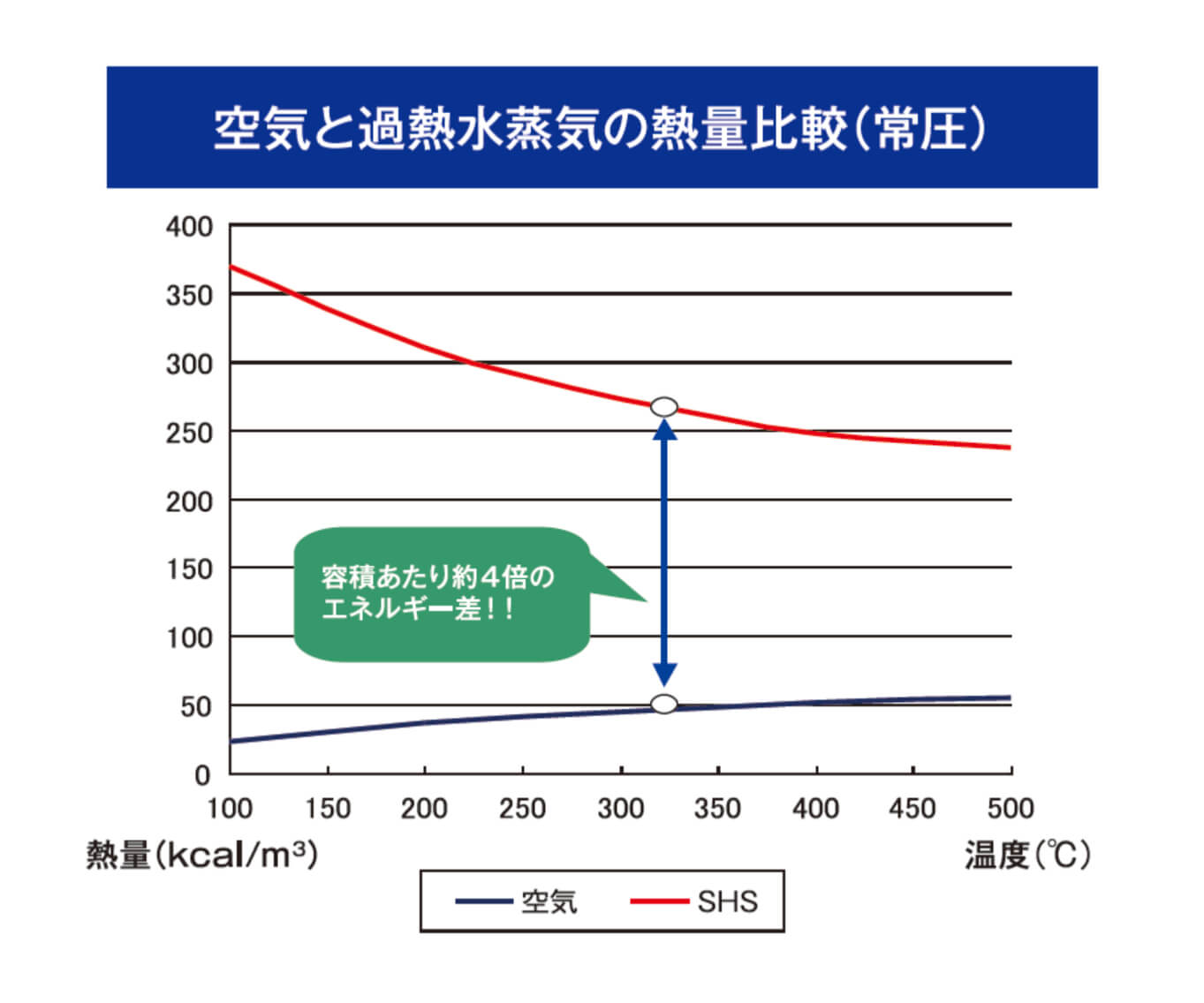

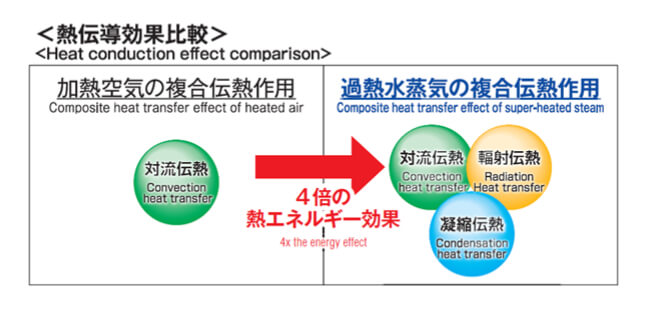

Superheated steam (SHS) has four times the thermal energy (per volume) compared to hot air, and can be heated by combined heat transfer of convection, radiation, and condensation.

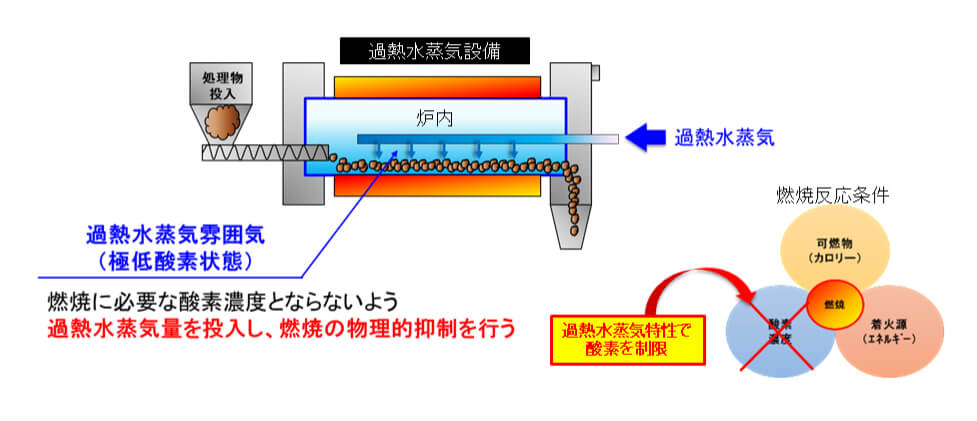

Under a superheated steam atmosphere, an extremely low oxygen atmosphere effect similar to that of an inert gas can be obtained, and oxidation suppression, thermal decomposition treatment, and carbonization treatment are possible.

Due to the characteristics of superheated steam (SHS), the treatment atmosphere is extremely low oxygen, so stable heat treatment can be achieved without combustion inside the furnace.

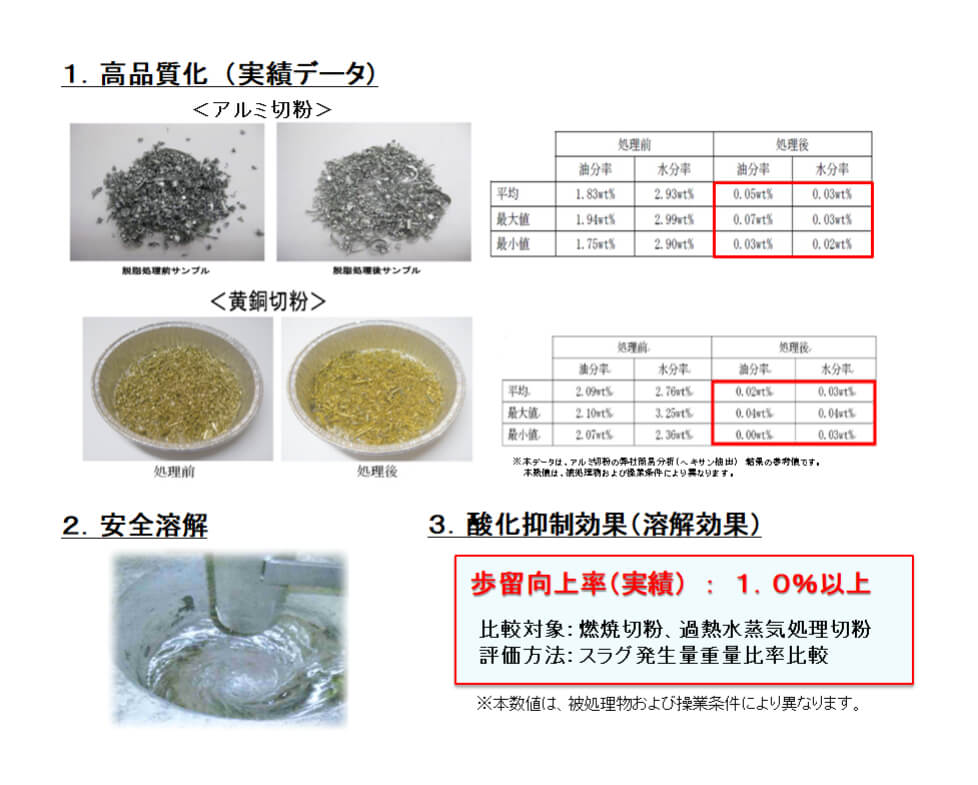

By using a superheated steam atmosphere, which has the same effect as inert gas, we aim to improve the quality of the processed material by suppressing oxidation.

(Improved yield and safe melting of metals by suppressing oxidation and reducing the amount of residual C)

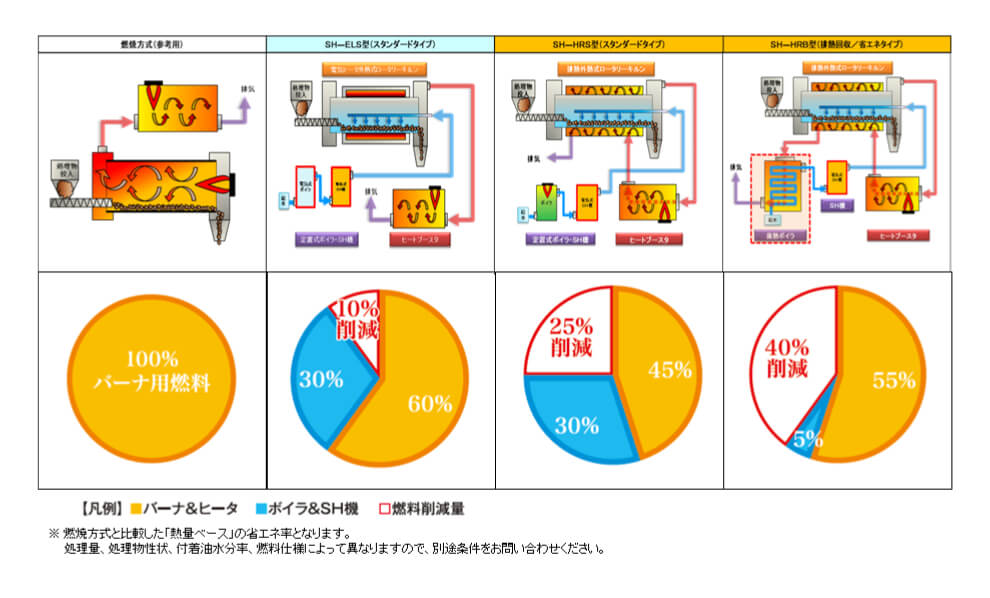

We make maximum use of the energy of the processed material and the waste heat generated, and perform heat recycling within the equipment system to reduce running costs (energy saving).

(Utilization as a heat source for increasing the temperature of equipment and energy for steam generation by a waste heat boiler)

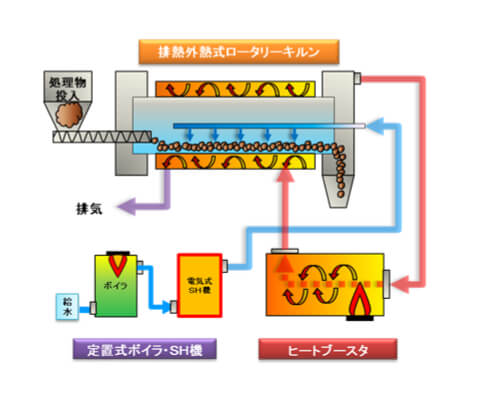

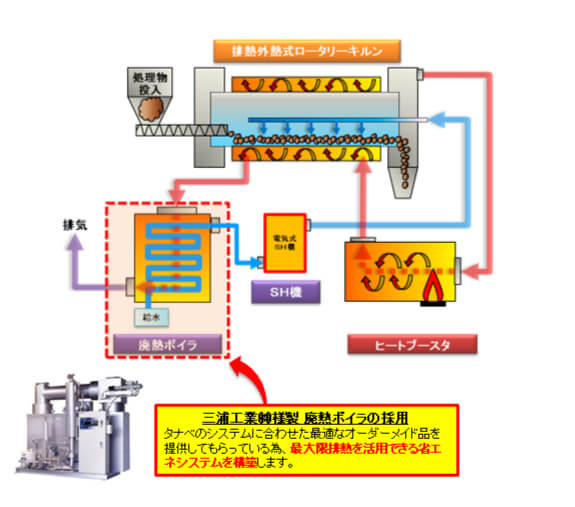

We propose the optimum pattern according to customer needs and processing conditions.

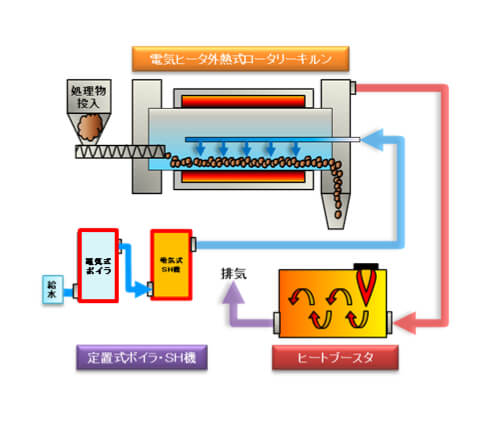

Easy operation and precise temperature control are possible by adopting an electric heater, and a type that can process up to a high temperature range (up to 800°C).

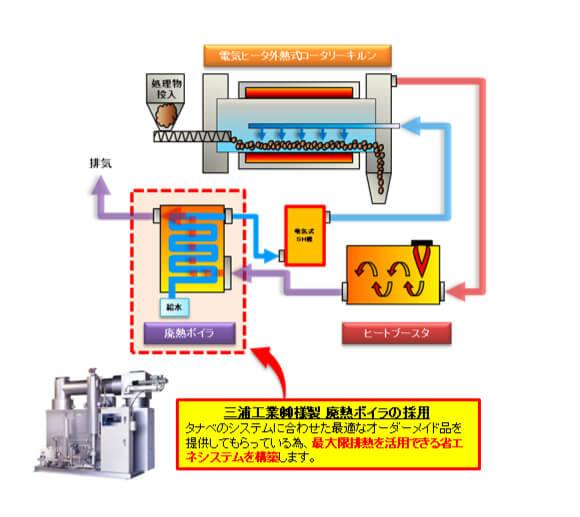

Easy operation and precise temperature control are possible by adopting an electric heater, and a type that can process up to a high temperature range (up to 800°C). In addition, by adopting a waste heat boiler, the energy used to generate steam can be saved.

An energy-saving type that thermally recycles the maximum amount of energy (calorie) in the processed material. By designing and utilizing exhaust heat, the optimum exhaust gas system that matches the calorific value of the processed material dramatically reduces the unit cost of processing.

An energy-saving type that thermally recycles the maximum amount of energy (calorie) in the processed material. By designing and utilizing exhaust heat, the optimum exhaust gas system that matches the calorific value of the processed material dramatically reduces the unit cost of processing. In addition, by adopting a waste heat boiler, the energy used to generate steam is saved.

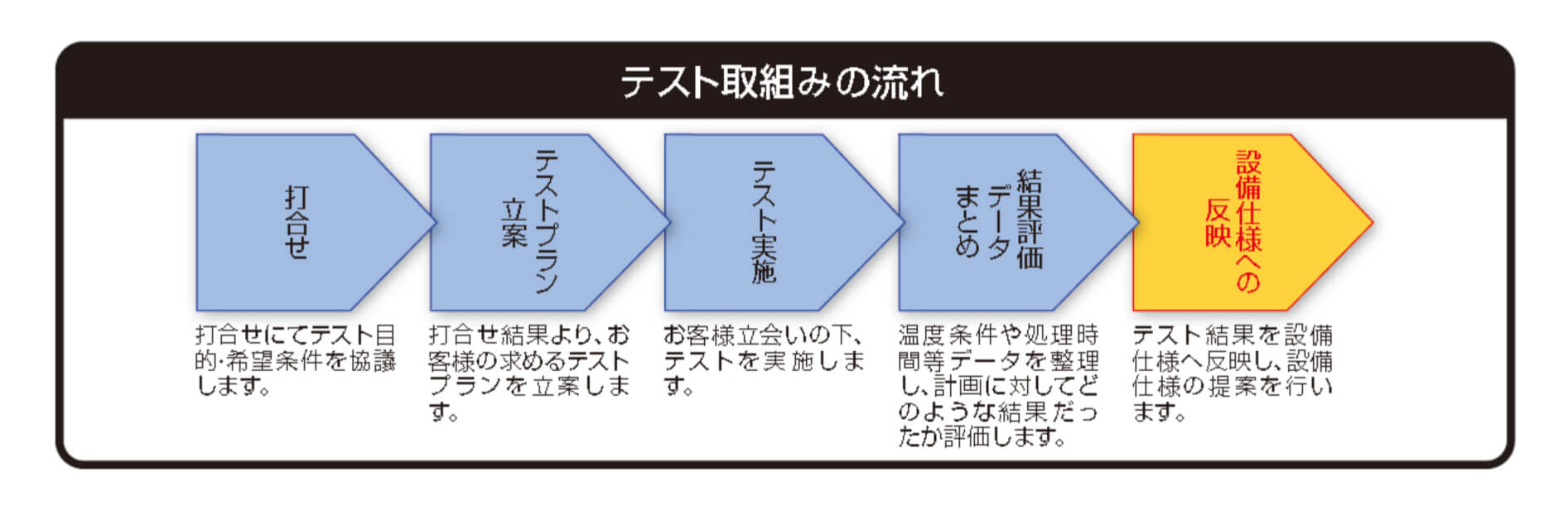

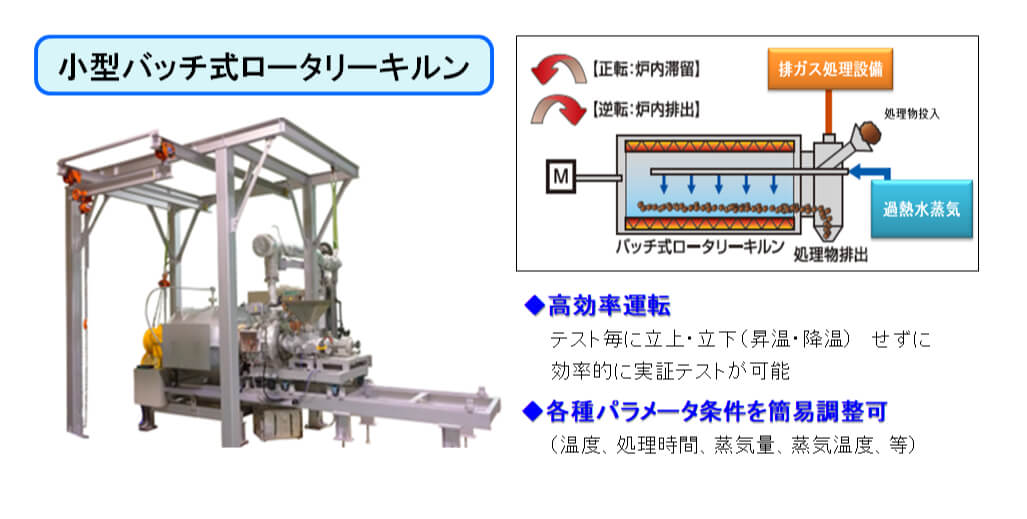

We can conduct verification tests for equipment introduction according to the customer's heat treatment needs for research and development purposes (variety improvement and next-generation powder development) or verification for rotary kiln.

It is a continuous rotary kiln and adopts an external heating method using an electric heater as a heat source, so temperature can be easily controlled.

It is a small batch type rotary kiln, which enables easy temperature control with electric heaters and easy performance evaluation of small batch samples.

Hot air circulation mesh belt type oven equipment. It is possible to test performance evaluation of deformed materials and parts materials that cannot be handled by rotary kilns.

Box type device for simple test (batch type)

Japanese Patent No. 4199758 "Mixed and mixed waste degreasing and recycling equipment"

Japanese Patent No. 4134150 "Magnesium alloy, degreasing treatment apparatus and degreasing treatment method for mixture containing magnesium alloy"

Service/Technical Information

Casting Division

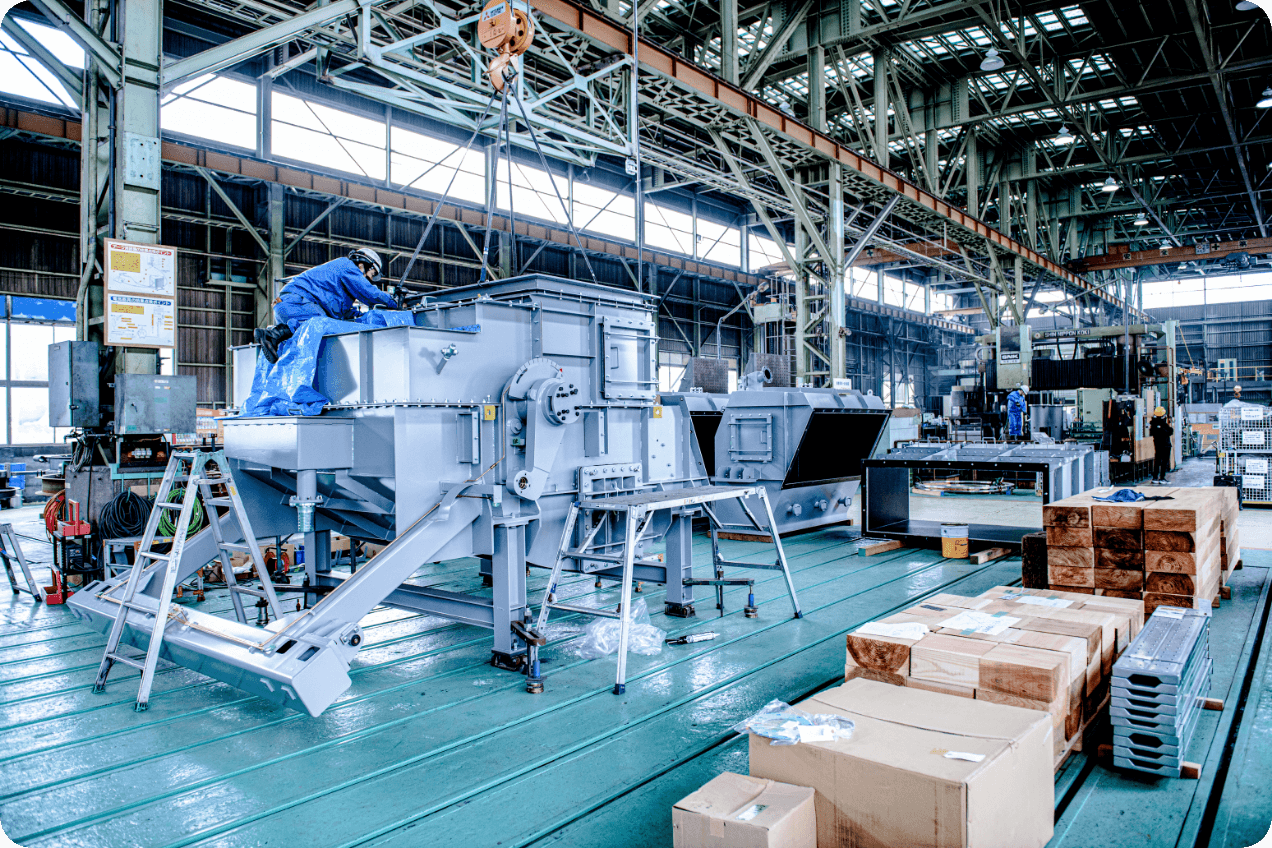

We specialize in highly difficult castings with multiple cores using the technology we have cultivated as a top manufacturer of various electric furnaces.

VIEW MORE

Procurement information

We are looking for a wide range of suppliers to cooperate with us in procuring materials, parts, equipment, and various services.

VIEW MORE

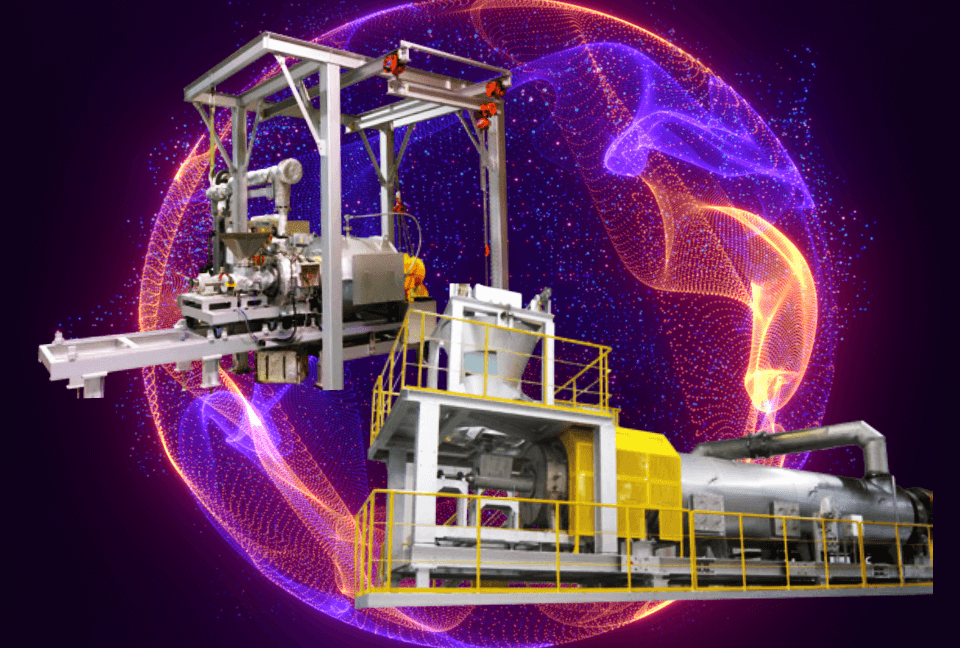

superheated steam technology

Introducing superheated steam technology, which has high energy density and thermal efficiency and is used in many industrial processes.

VIEW MORE

Contract manufacturing

This is a contract manufacturing business that utilizes our own manufacturing and processing equipment such as electric furnaces and rotary kilns.

VIEW MORECONTACT

To Tanabe, world-recognized thermal technology

Please feel free to contact us.