Product Info

ROTARY KILN

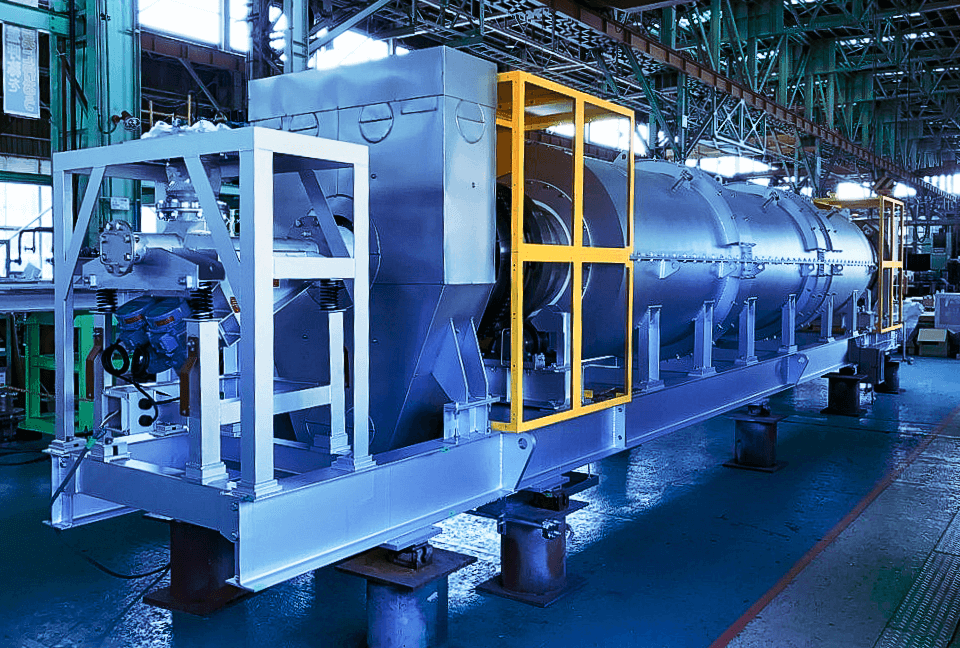

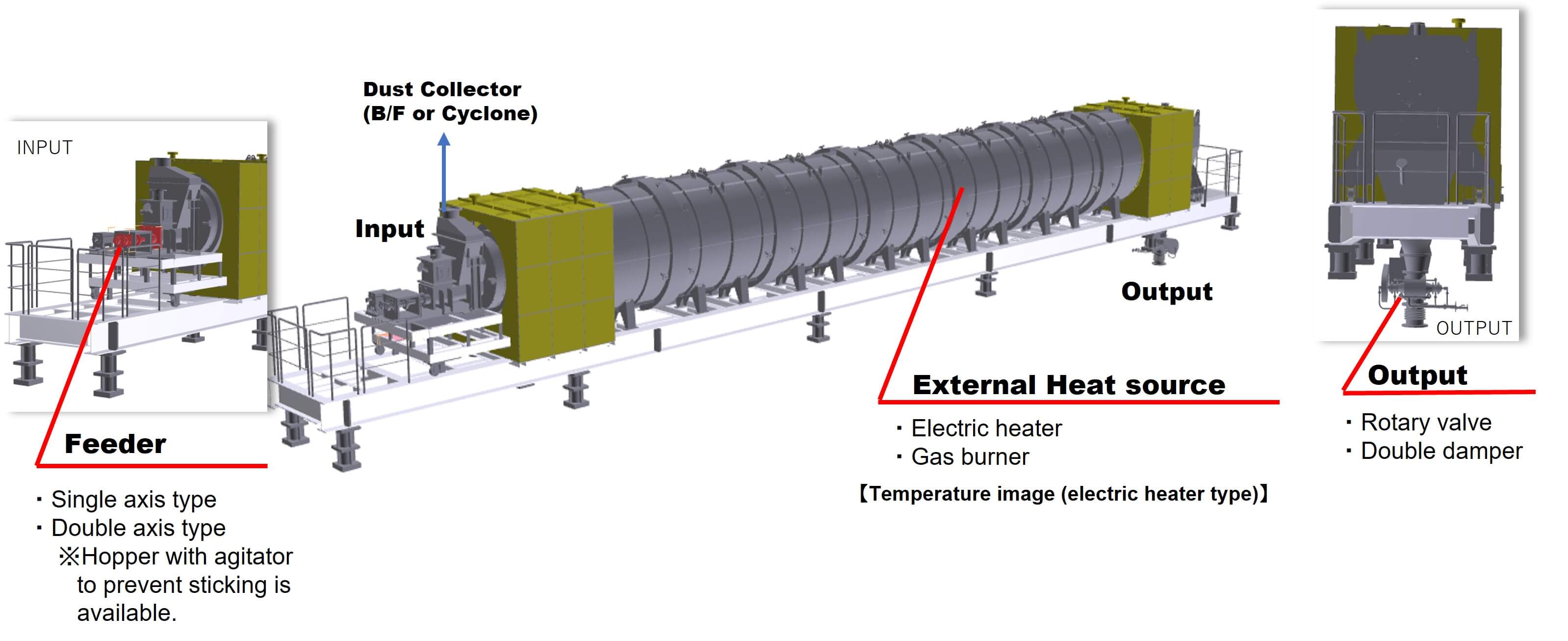

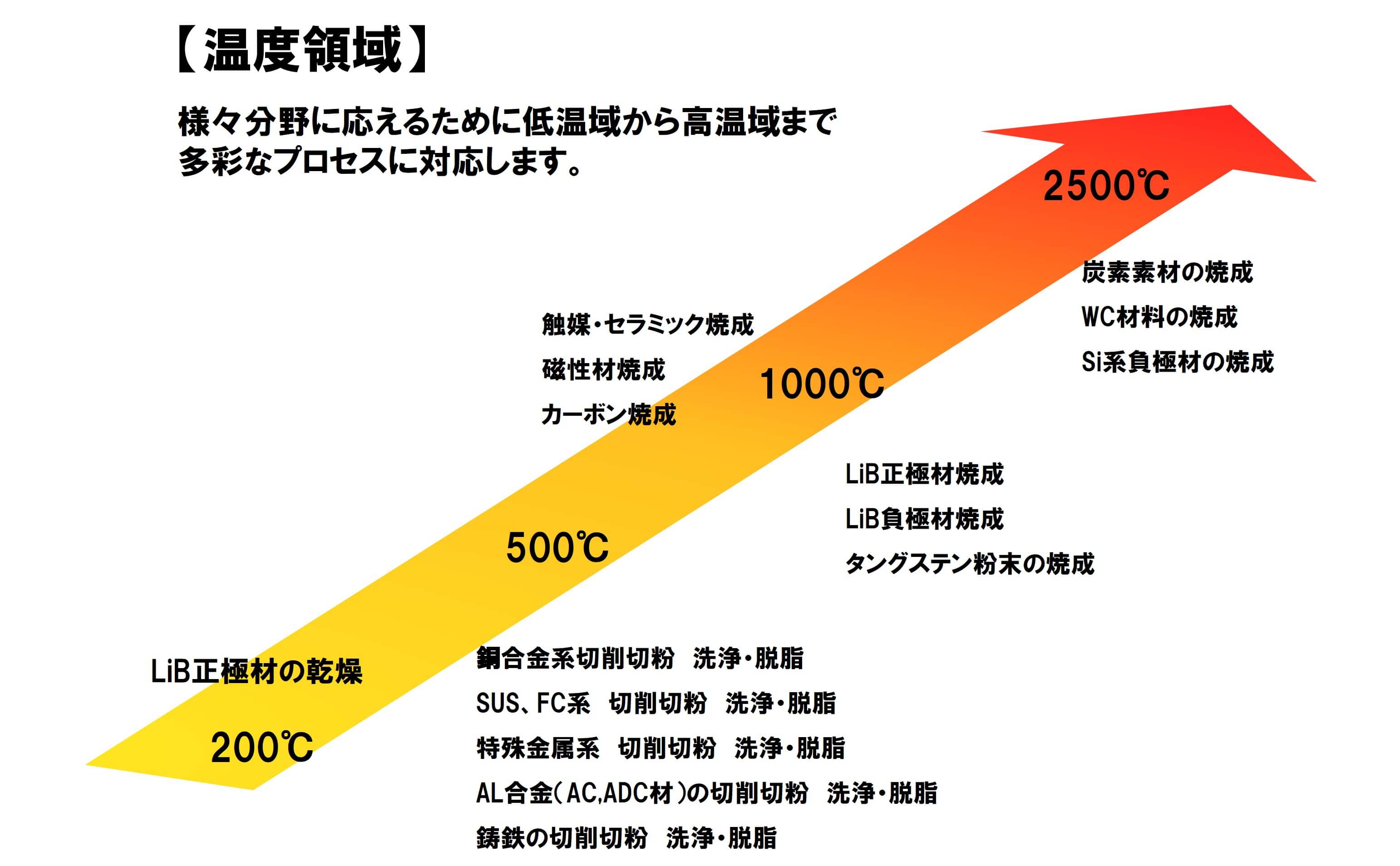

A rotary kiln is a heating furnace that rotates a cylinder (retort), supplies raw materials into the furnace (inside the retort) using a feeding device (screw feeder, etc.), and uniformly heat-treats the raw materials while stirring. At Tanabe, we handle a variety of processes from low-temperature ranges to high-temperature ranges (200℃ to 2500℃) in order to respond to various fields.

A rotary kiln is a heating furnace that rotates a cylinder (retort), supplies raw materials into the furnace (inside the retort) using a feeding device (screw feeder, etc.), and uniformly heat-treats the raw materials while stirring. Rotary kilns usually have a slight slope with respect to the horizontal, allowing raw materials to be heated while gently rotating the cylinder (retort). At Tanabe, we handle a variety of processes from low-temperature ranges to high-temperature ranges (200°C to 2500°C) in order to respond to a variety of fields. please).

There are two main types of rotary kilns: batch and continuous. There are some differences between these two.

Which type of rotary kiln is most suitable depends on the processing requirements and production goals (please inquire individually for details of applications and processing volumes that Tanabe can handle).

There are two main differences in heating methods for rotary kilns: electric heaters and gas burners.

Electric heaters can usually heat up to high temperatures, but it is relatively easy to control the heating rate and temperature. Another feature is that it is easy to uniformly control the temperature distribution inside the kiln. The atmosphere inside the furnace can be air (including decarbonated air), oxygen, nitrogen, argon, etc.

The gas burner type uses heat derived from the processed material as fuel (heat source) for the heat booster. This is an energy-saving facility that utilizes the generated waste heat as an external heat source. Superheated steam (SHS) corresponds to the furnace atmosphere.

It will be supported by the carbon heater kiln.

Safely removes adhering oil and moisture from aluminum chips (active metals) that often cause fires and explosions, realizing stable operation and improved added value. View product details

We propose a superheated steam system with high added value and energy saving compared to the conventional method (direct combustion type, etc.). View product details

Even if it contains waste plastic or waste with a large amount of heat, and general pretreatment (combustion type) is difficult, it can be safely treated by using the superheated steam system. View product details

Safely removes surface coatings, deposits, and organic matter from metal resources (waste and valuables). View product details

From small machines to mass-produced machines, we propose optimal designs that meet the needs of processing items, processing fees, ancillary equipment, installation space, etc. View product details

Batch-type rotary kiln is recommended for samples that require long-time firing (4 hours or more). As with the continuous rotary kiln, various atmosphere gases are inserted into the furnace and the raw material is fired while stirring. View product details

Batch-type rotary kiln is recommended for samples that require long-time firing (4 hours or more). As with the continuous rotary kiln, various atmosphere gases are inserted into the furnace and the raw material is fired while stirring. The small tester makes it easy to evaluate the firing of small amounts of high value-added raw materials. View product details

In addition to the rotary kiln itself, we propose total engineering that meets customer needs, from raw material cooling equipment after kiln discharge to exhaust gas treatment (deodorization and dust collection) equipment. In addition, we can also design and manufacture only incidental equipment, so if you have any incidental equipment you want, please contact us.

We provide equipment that cools the raw material discharged from the rotary kiln by thermal conduction of the cooling jacket structure. View product details

We provide equipment that cools the raw material discharged from the rotary kiln by heat conduction in a trough with a water-cooling jacket structure. View product details

Ancillary equipment that oxidizes and decomposes odorous components contained in exhaust gas at high temperatures using a burner, etc. View product details

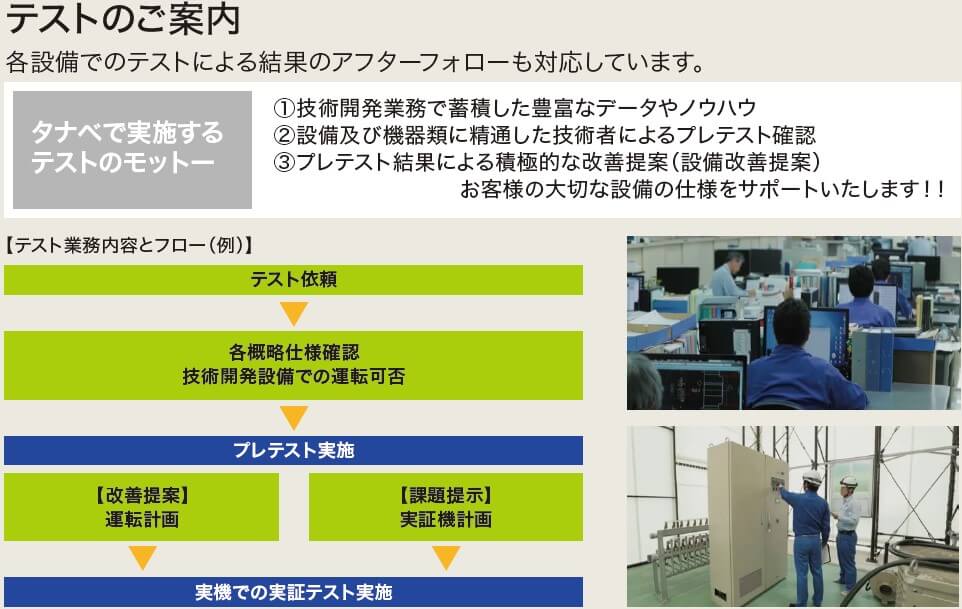

We can conduct verification tests for equipment introduction according to the customer's heat treatment needs for research and development purposes (variety improvement and next-generation powder development) or verification for rotary kiln.

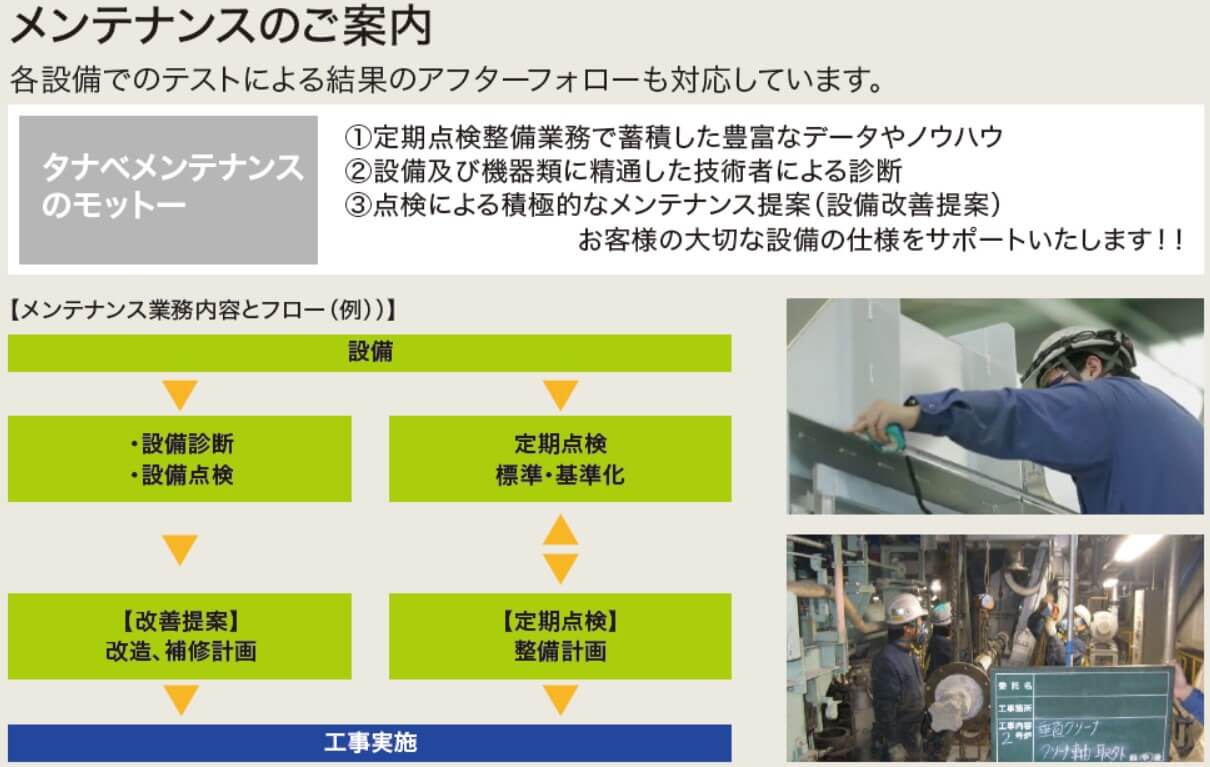

We will enhance the outer service after delivery of the rotary kiln and contribute to the creation of the optimal operating environment for our customers.

regular maintenance

We propose the best maintenance according to the customer's shutdown period.

・Cleaning and replacing the seal part

・Soundness check of external cylinder heater

・Cleaning inside the furnace and confirming soundness

・Cleaning inside the furnace and confirming soundness

・Replacing consumables such as rollers, etc.

spare parts sales

We have various consumables and spare parts necessary for stable operation. We also offer equipment diagnosis during regular maintenance.

Support for remodeling work

We are carrying out remodeling work to realize further functions, such as remodeling the in-furnace mechanism to strengthen production capacity and change products.

We have testing equipment, so we can check the workmanship. After confirming the details of the test, both companies will decide whether or not to respond.

Powder processing requires not only a rotary kiln (heating furnace) itself, but also various pre- and post-processing equipment and exhaust gas processing equipment. Therefore, we propose a variety of auxiliary equipment according to the needs of our customers.

Mainly air (including decarbonated air), oxygen, nitrogen, argon, and superheated steam. After consulting with us about other matters, we will decide whether or not we can respond.

We also handle regular maintenance, spare parts sales, and remodeling work. It is also possible to support only instructors or collaborate with maintenance companies.

We have a track record of many deliveries to Asia and Europe. We can also deliver to other countries, so please contact us.

We have continuous type φ300RK x 2 units (for special powder / 1 unit), continuous type φ100 x 1 unit, carbon heater kiln x 1 unit, small batch type rotary kiln (φ400), so from the verification test We can proceed.

The rotary kiln itself cannot be made explosion-proof. Explosion-proof specifications can be partially selected for instrumentation equipment, etc.

The maximum cylinder diameter (retort diameter) is φ1,400. The processing capacity is approximately 1,900 to 2,600 L/h (reference guideline for φ1400 RK).

If it is up to 900℃, it is possible to handle it with an electric rotary kiln. A carbon heater kiln can handle temperatures from 1,000°C to 2,500°C.

We handle SUS materials and other special alloys, so it is possible to change. However, we do not handle ceramic materials.

rotary kiln

.jpg)

Superheated steam type small batch furnace

.jpg)

Superheated steam type small batch type rotary kiln

.jpg)

Superheated steam delacquering system for aluminum cans (UBC)

(For lab tests) Small size continuous external heat rotary kiln

Direct combustion deodorizing furnace for exhaust gas treatment (burner method)

.jpg)

Continuous external heat rotary kiln (electric)

Medium size batch type external heat rotary kiln (electric type)

Small size batch type external heat rotary kiln (electric type)

Continuous screw feeder for raw material cooling

Medium size (for demonstration test) Continuous external heat rotary kiln (electric)

Compact size (for development testing) Continuous external heat rotary kiln (carbon heater method)

Continuous rotary cooler for raw material cooling

.jpg)

Superheated steam type organic matter removal system for metal waste

.jpg)

Superheated steam cleaning and degreasing system for various metal chips

.jpg)

Superheated steam cleaning/degreasing system for aluminum chips (active metals)

CONTACT

To Tanabe, world-recognized thermal technology

Please feel free to contact us.