Product Info

HEATING FURNACE

A heating furnace is a device used to heat an object to a specified temperature between low and high temperatures. In recent years, Tanabe has been recommending electric systems due to CO2 reduction and carbon neutrality.

A heating furnace is a device that is used to heat materials to a specified temperature from low to high temperatures. To maintain the temperature, heat is pumped inside the furnace. The equipment is different depending on the heat source, such as electric or gas, and the size and configuration of the equipment also changes depending on the material to be processed. At our company, in recent years, we recommend electric type due to CO2 reduction and carbon neutrality.

Equipment planning for low to high temperatures is possible. There are various types of furnace atmospheres, including inert gas (nitrogen, argon, etc.), oxidizing gas (oxygen, etc.), reducing gas (hydrogen, ammonia, etc.), and carburizing gas (carbon monoxide, hydrocarbon gas). Equipment suitable for the processing time, such as a continuous furnace or a batch furnace. Automation including the door can also be supported. Electric type, gas type (city gas, propane, LNG) and liquid fuel type (heavy oil, kerosene) are available.

A furnace that heats an object using thermal energy. Widely applicable and used in all industrial applications. Currently, there are electric furnaces and gas furnaces.

Resistance heating is the principle of generating heat using electrical resistance. In a resistance heating furnace, a heating element (heater) made of highly conductive material is passed through an electric current to generate heat called Joule heat. A heater heats an object by directly contacting it and transferring heat.

Induction heating is a principle that creates a high-frequency electromagnetic field that induces an induced current in an object to generate heat. In induction heating furnaces, high-frequency coils (induction coils) are made and electromagnetic fields act on objects. When an object is exposed to an electromagnetic field, an induced current is generated within the object, creating Joule heat and heating the object.

There are several common methods of cooling furnaces. Some typical cooling methods are described below.

Natural cooling is a method in which the furnace is left to cool naturally after the heating process. This is a simple and low cost cooling method as the heat in the furnace is naturally dissipated to the surrounding environment. However, the cooling time may be relatively long.

Forced cooling is the method of using fans or chillers to increase the cooling rate of the furnace. A fan circulates cooling air through the furnace and expels heat efficiently. This will reduce the cooling time. Forced cooling is effective in processes where cooling speed is important or when it is necessary to move quickly to the next step.

Water cooling is a method of cooling a furnace using water. Cooling water circulates through cooling channels and pipes in the furnace, absorbing and discharging heat. Water cooling has high cooling capacity and controllability, and is effective in high temperature and high heat load situations.

Gas cooling is a method of cooling the heating furnace with gas. Typically, cooling gas passes through the furnace, absorbing heat and cooling. This method is particularly suitable for cooling hot processes and certain raw materials. Cooling gas types include nitrogen, helium, and argon gas.

Furnace cooling methods are selected according to the raw materials used and the requirements of the process. We select the appropriate cooling method by considering factors such as cooling speed, uniformity of cooling, and energy efficiency.

A batch heating furnace is a method that heats a fixed amount of raw materials (batch) at a time. The raw material is put into the furnace, goes through a series of heating processes, and is taken out. Heating time and temperature can be adjusted for each process. Batch-by-batch operations are required and the amount of raw material that can be processed at one time is limited. Conditions can be changed for each process.

A continuous heating furnace is a method in which raw materials are continuously supplied and heated at a constant rate. The raw material passes through the furnace and is processed through a series of heating zones. Higher productivity than batch type due to continuous feeding and discharging. The heating time and temperature are constant, ensuring consistent quality throughout the process.

A tubular furnace is a method in which raw materials are passed through a long tube and the circumference of the tube is heated. The raw material flows at a constant speed and passes through the heating zone. A tubular furnace is a form of continuous heating furnace that provides continuous supply and uniform quality. In addition, specific reactions and heat treatments are possible by controlling the shape of the tube and the flowing raw materials.

Elevating heating furnace is a method of heating raw materials using an elevating platform with a heating zone. Raw materials are placed on a platform and heated while being raised and lowered as needed. This method enables uniform heating of the bottom and sides of the raw material, and is suitable for processing complicated-shaped or large-sized raw materials.

This method heats the raw material while rotating it. By heating the raw material while rotating it, even heating and uniformity can be obtained.Click here for details

Heating device for deformed material. After heating, this is a special heating device that includes a transfer device that carries the material to the next process, the furnace itself moves, and the material is collected and transferred by an arm. View product details

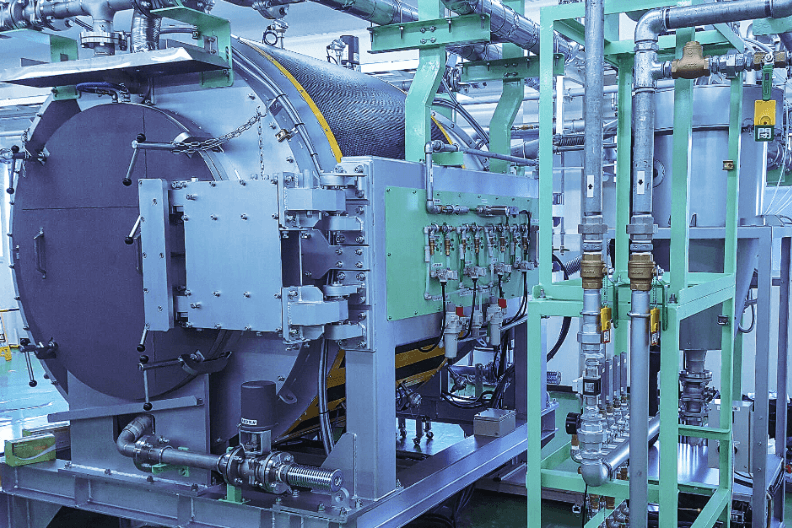

A vacuum furnace for drying ceramic raw materials, firing, and firing and drying special metals.View product details

A mesh belt oven for continuous drying and baking of irregular shaped objects.View product details

We provide energy-saving and high-efficiency inter-feed annealing equipment that performs bright annealing in an inert atmosphere by directly reducing and burning enameled wires or aluminum wires with fuel gas. View product details

We provide energy-saving, high-speed enameled wire baking furnaces that operate enameled wire or aluminum wire using both a direct combustion burner and a catalytic combustion heat recovery system. View product details

Carbon heater type high temperature vertical heating furnace (crucible type). View product details

This is a comprehensive facility that combines a furnace and a transfer device. It is also possible to design a transfer device that transfers the processed material between heating furnaces. View product details

We can design and manufacture gas type exhaust gas equipment. View product details

This is a preset type device that determines the opening of the gas/air control damper by operating the touch panel and controls the air-fuel ratio. View product details

We can conduct verification tests for equipment introduction according to the customer's heat treatment needs for research and development purposes (variety improvement and next-generation powder development) or verification for rotary kiln.

Demonstration test/examination

We are performing maintenance on the delivered equipment. From half a year to a year, please make a request each time. Our company can make proposals according to the customer's request, such as dispatching only a supervisor or including workers.

Furnace temperature measurement is mainly used by installing a temperature measuring instrument inside the furnace and non-contact measurement such as a radiation thermometer. The control method is to connect the thermometer to the control device and perform automatic control.

There are a wide variety of heating furnaces such as heating furnaces and vacuum furnaces. It varies depending on temperature, size, material used, atmosphere, etc. We provide custom-made equipment and facilities while listening to the needs of our customers.

The heating furnace itself cannot be made explosion-proof. Explosion-proof specifications can be partially selected for instrumentation equipment, etc.

We have a small test machine for heating furnaces. We listen to what our customers want. It is carried out under various conditions such as the required sample amount, temperature, and atmosphere. The place where the test equipment is located is the head office (Itoigawa City, Niigata Prefecture).

We have a track record of delivery to various countries. There are many Asian regions for heating furnaces, and we also have a track record in the United States and France.

The atmosphere inside the furnace is mainly an air atmosphere or an inert atmosphere. Compatible with argon gas, nitrogen gas, etc.

We provide maintenance support. We conduct semi-annual inspections and annual inspections based on our proposals and customer requests. If there are equipment maintenance workers at the customer's business office or factory, we may dispatch only instructors from our company to cooperate with them. We also provide support including workers.

As a result, we have manufactured a 17m x 11m x 2mH disk-shaped heating furnace, although the maximum size is connected. In this method, the products to be processed are placed in a predetermined place, and a box with a heater installed is placed on top and connected. Since there are many heating furnaces with different specifications, we listen to customer needs and make optimal proposals.

heating furnace

.jpg)

Superheated steam cleaning and degreasing system for chip briquettes

Conveyor

Direct combustion deodorizing furnace for exhaust gas treatment (burner method)

vacuum furnace

baking furnace

/掲載写真1-rotated.jpg)

Vertical high temperature furnace (large)

/掲載写真1-scaled.jpg)

Vertical high temperature vacuum furnace (small size)

Automatic transfer heating furnace

Air-fuel ratio controller

Annealing Furnace / Annealing Furnace (for manufacturing enameled wire and aluminum wire)

.jpg)

Superheated steam mesh belt oven

CONTACT

To Tanabe, world-recognized thermal technology

Please feel free to contact us.