Service/Technical Information

SERVICE

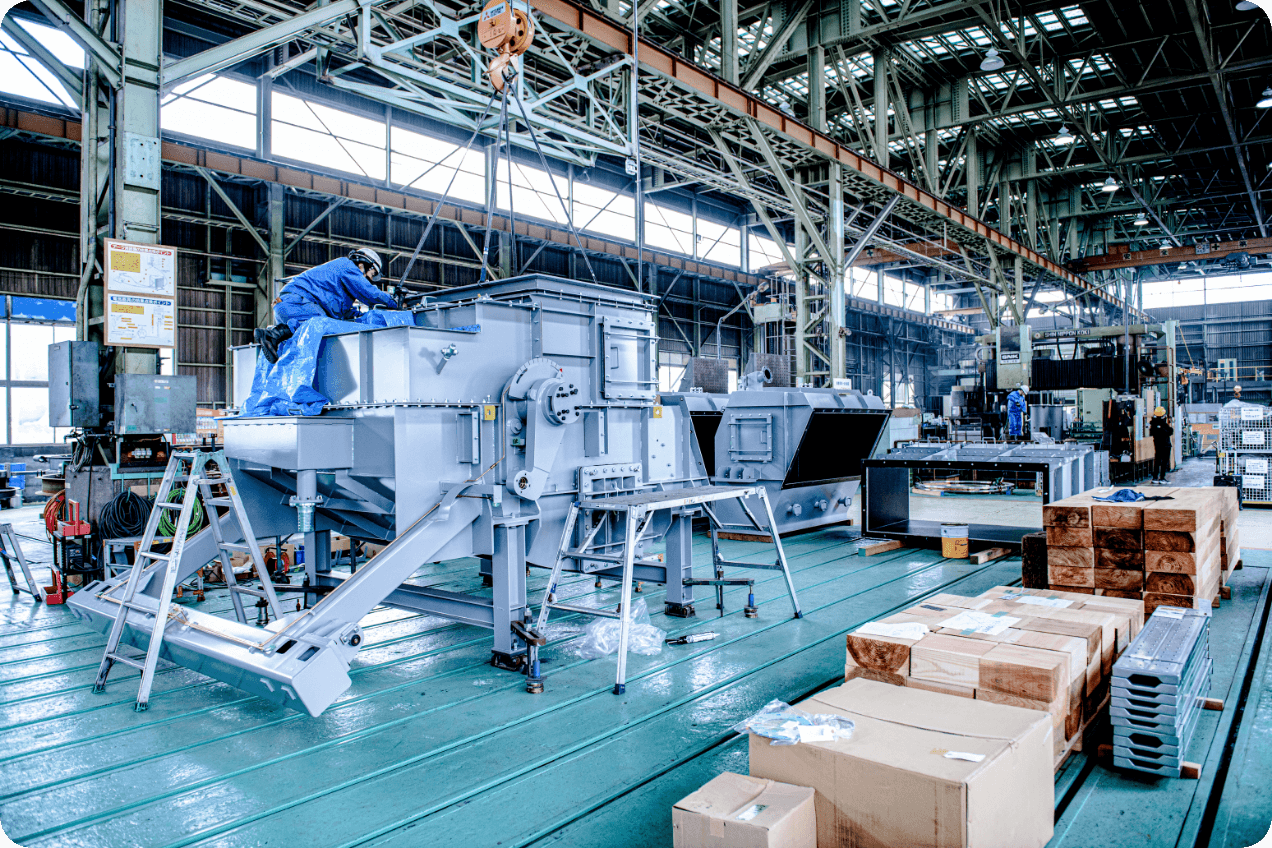

We are developing a contract manufacturing business that utilizes our own manufacturing and processing equipment such as electric furnaces and rotary kilns. We also handle orders that include material procurement and orders based on materials supplied by the ordering party.

Material procurement agent/machine parts processing

SERVICE-1

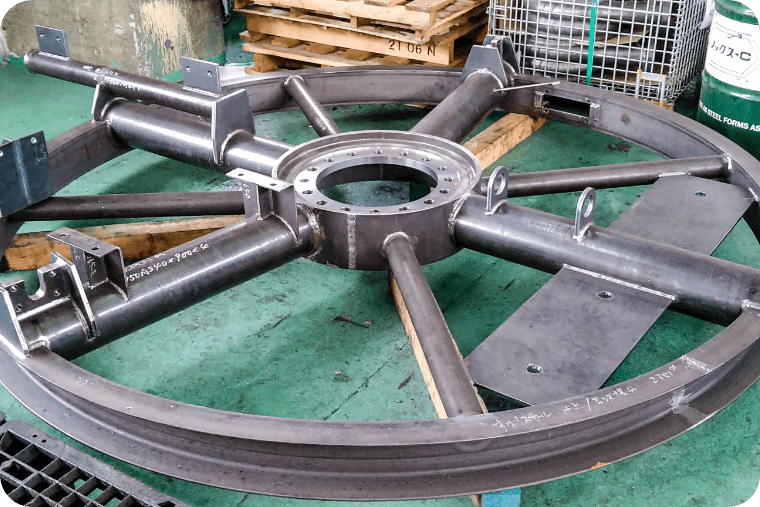

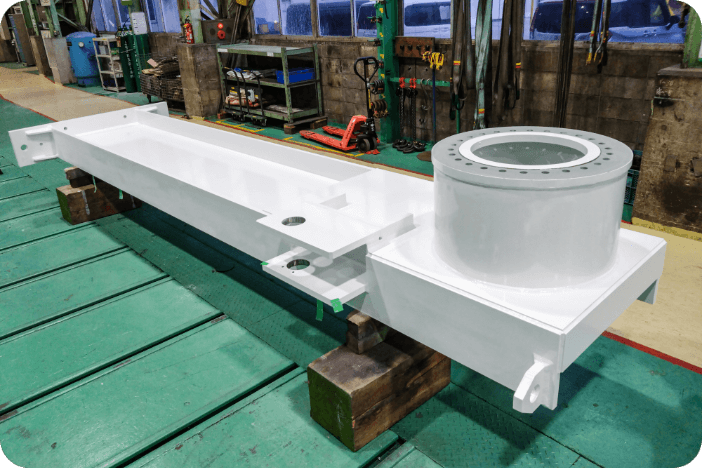

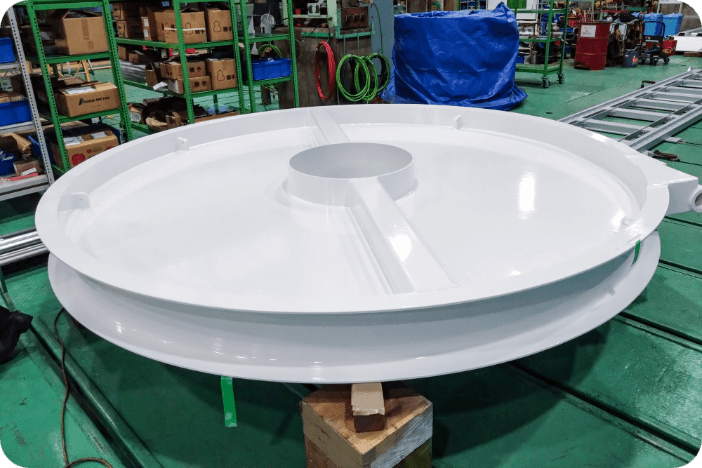

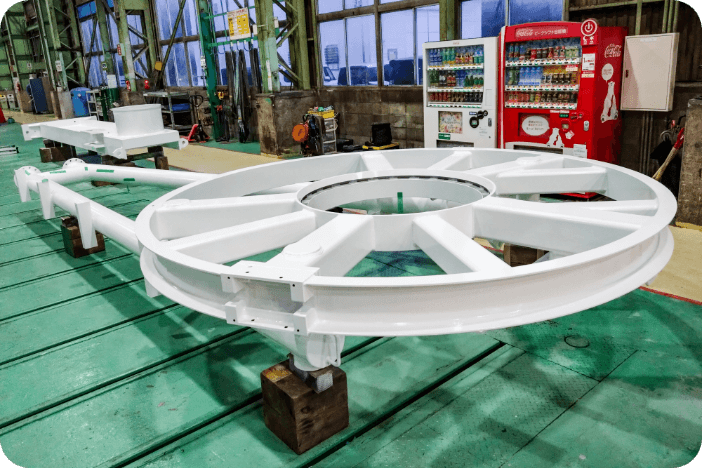

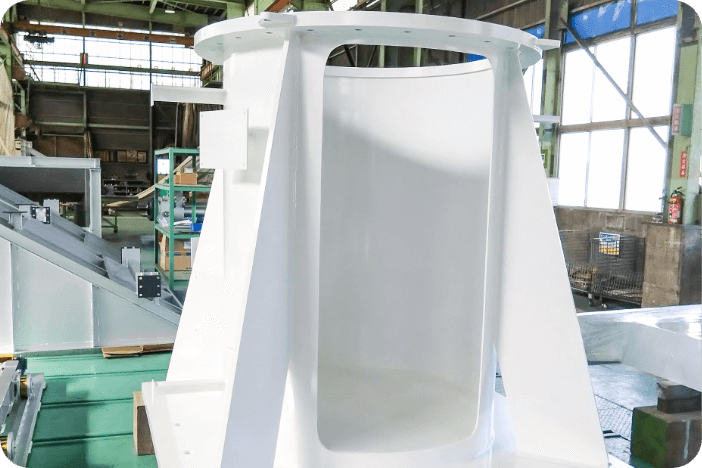

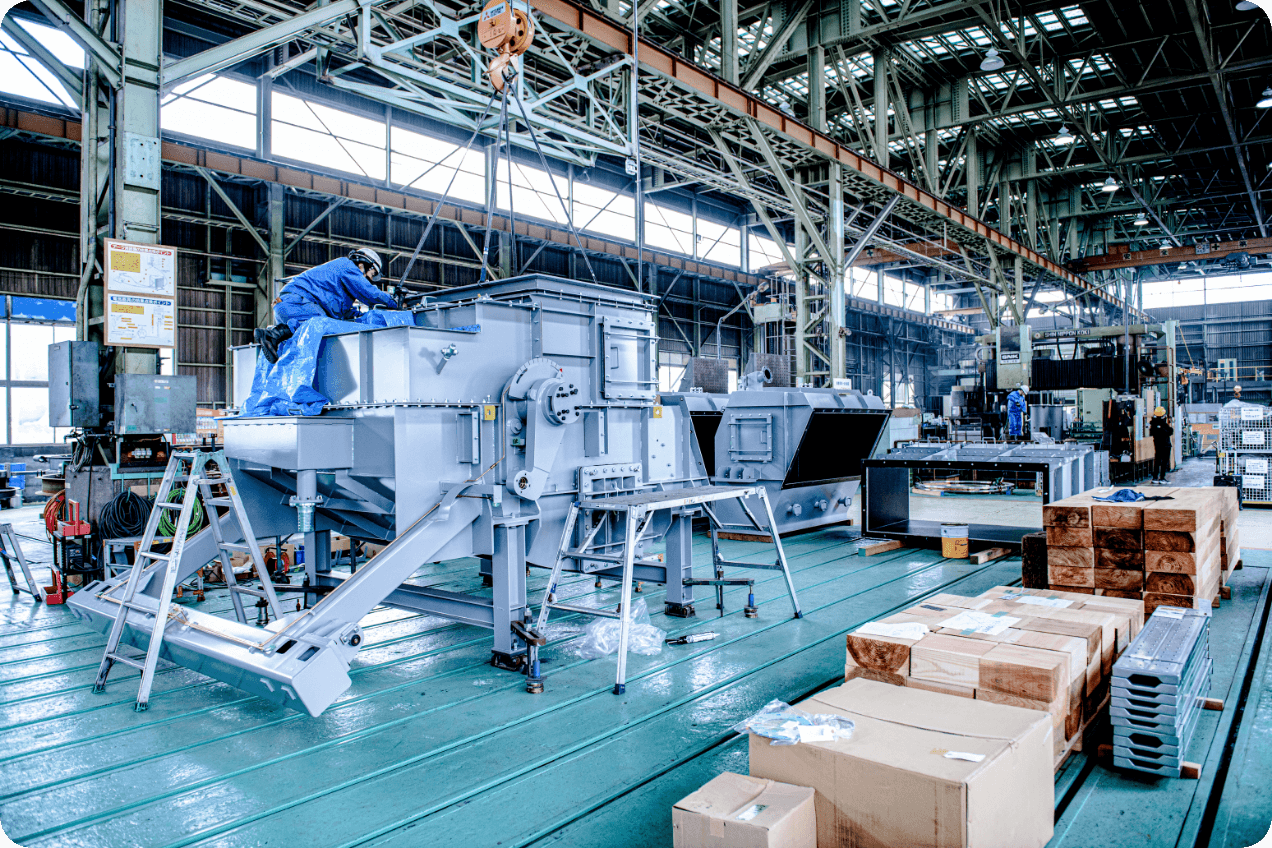

Taking advantage of one of the largest site areas, building scales, crane capacities, and processing equipment in the Joetsu area, we can manufacture individual parts (machine processing, press molding, laser processing), partially machine finish, weld canned products, and We can provide a wide range of support, including large can manufacturing products based on drawings and specifications, manufacturing of machinery, painting, inspection, and consistent contracting from assembly to installation.

SERVICE-2

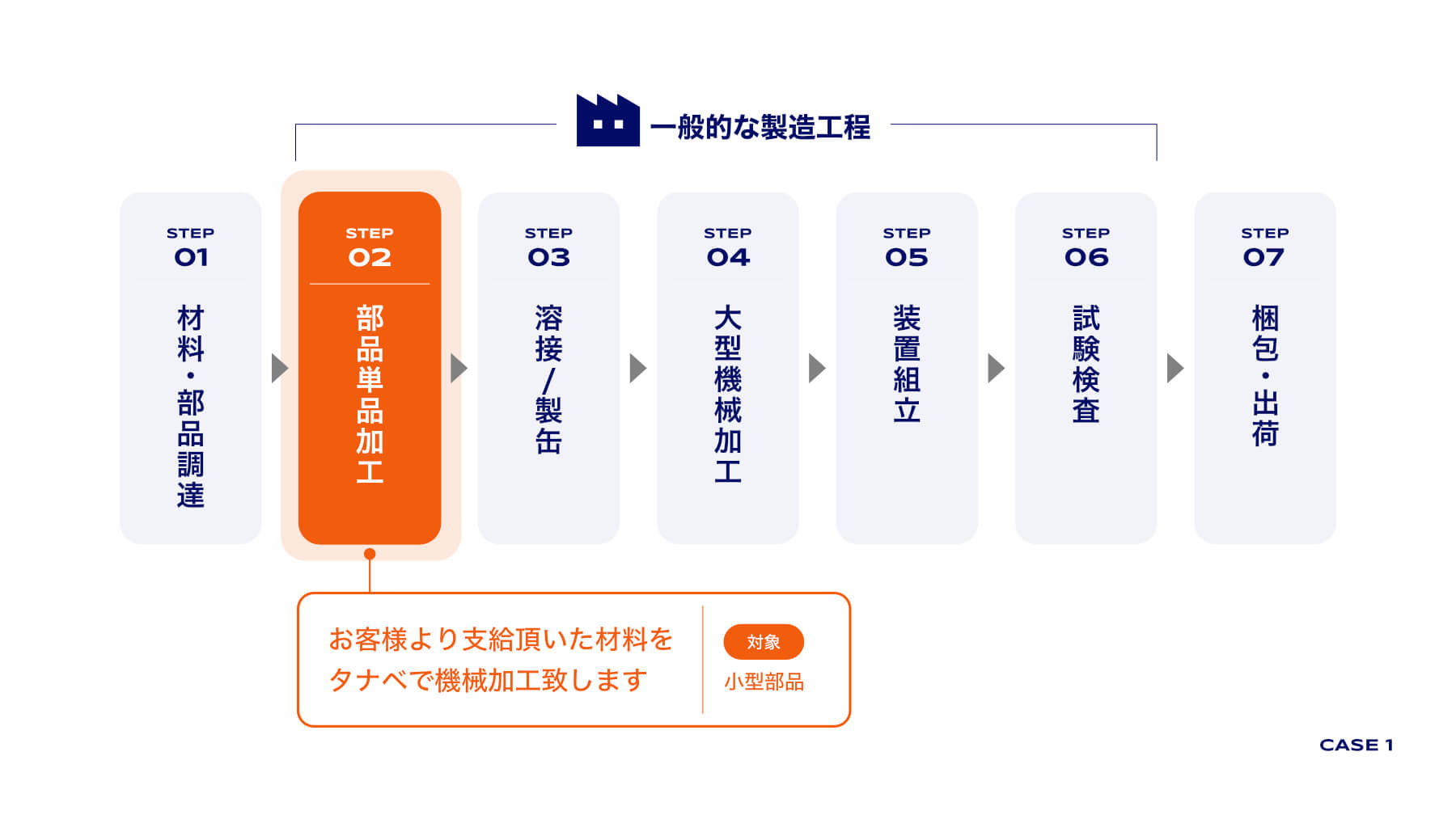

We machine materials provided by customers. In addition to machining, we can also handle laser cutting and press processing.

The shape of the supplied material is not important. We can cut standard length bars, tubes, and large plates to the size of the parts and machine them.

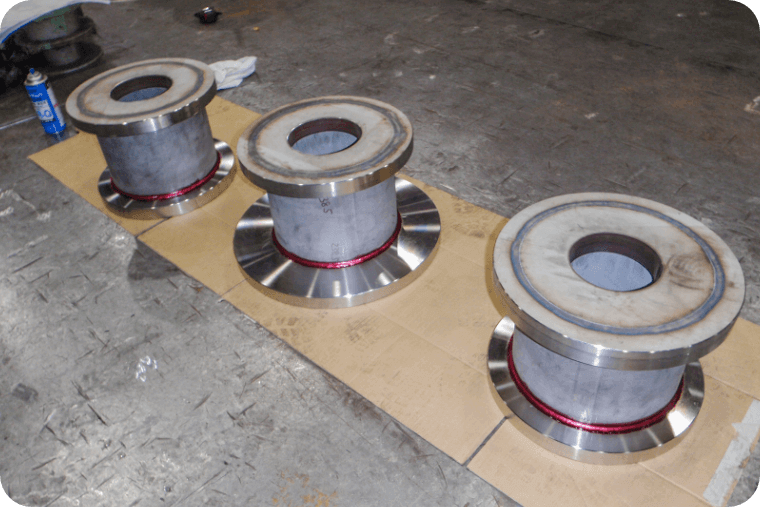

Tanabe will machine and finish large machine parts that have been welded and assembled by the customer.

We can process products weighing up to 20t on a gantry machining center and up to 10t on a vertical lathe. There are size restrictions, so please contact us for details.

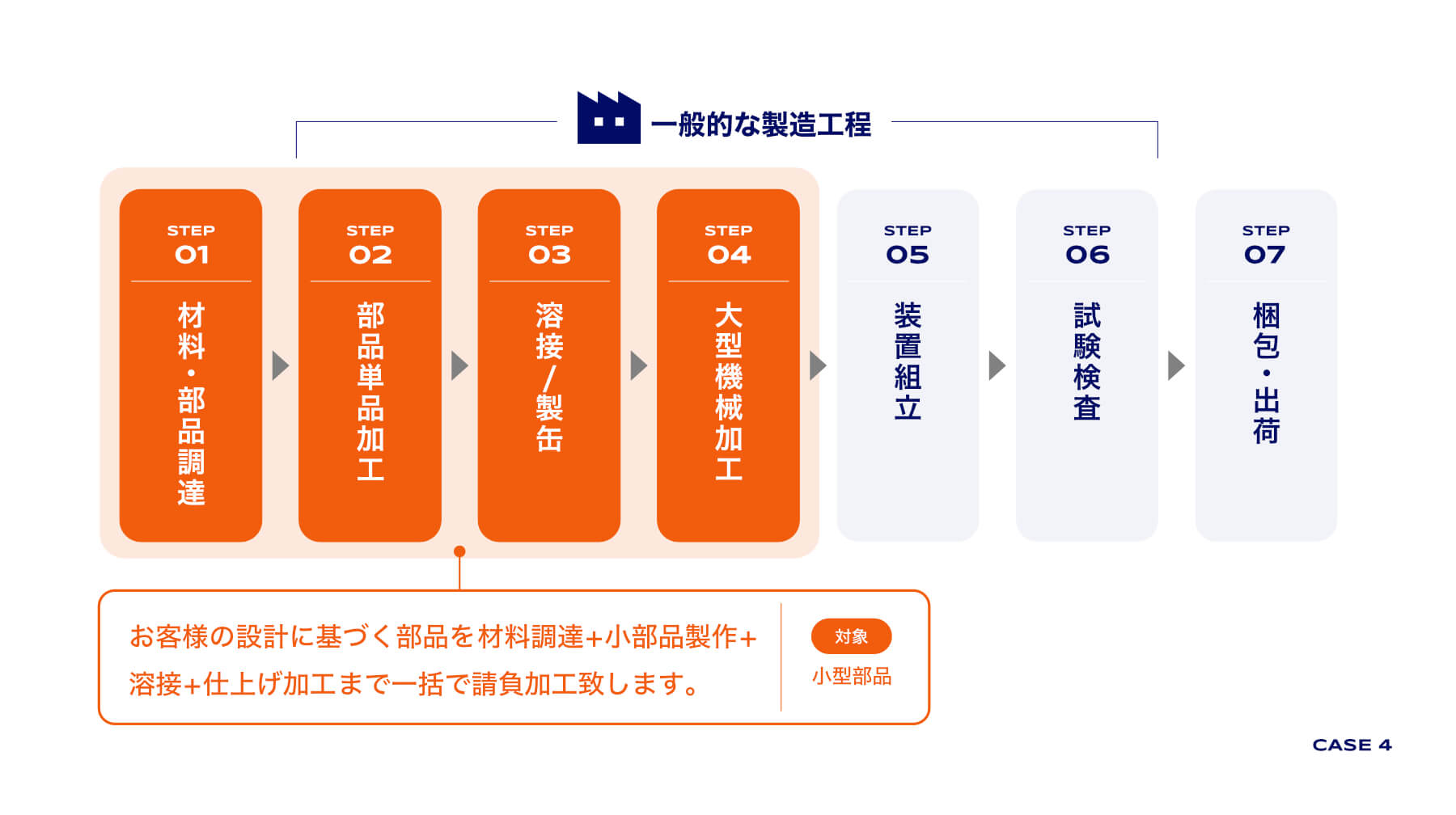

We manufacture and process parts based on customer designs, including procuring materials.

By taking on the entire process, including material procurement, we are able to reduce the production management burden on our customers.

We provide a one-stop contract processing service for parts based on customer designs, including material procurement, small part manufacturing, welding, and finishing.

By entrusting us with multiple processes, we can help reduce the management burden on our customers and shorten delivery times. We can also undertake blast finishing and painting after processing.

SERVICE-3

| Gate type machining center | Processing range: W2,900×L8,250×H1,600 Maximum workpiece weight: 20t |

|---|---|

| Vertical lathe | Processing range: φ4,000×H1,500 Workpiece maximum weight: 10t |

| press machine | Maximum pressure: 600 tons |

| Bending machine (bending roller) | Maximum board width: 3,000mm Maximum board thickness: 19mm |

| TIG welding machine | |

| crane | Capacity 20t, 15t, 10t, etc. Height under crane 12m |

SERVICE-4

Service/Technical Information

Casting Division

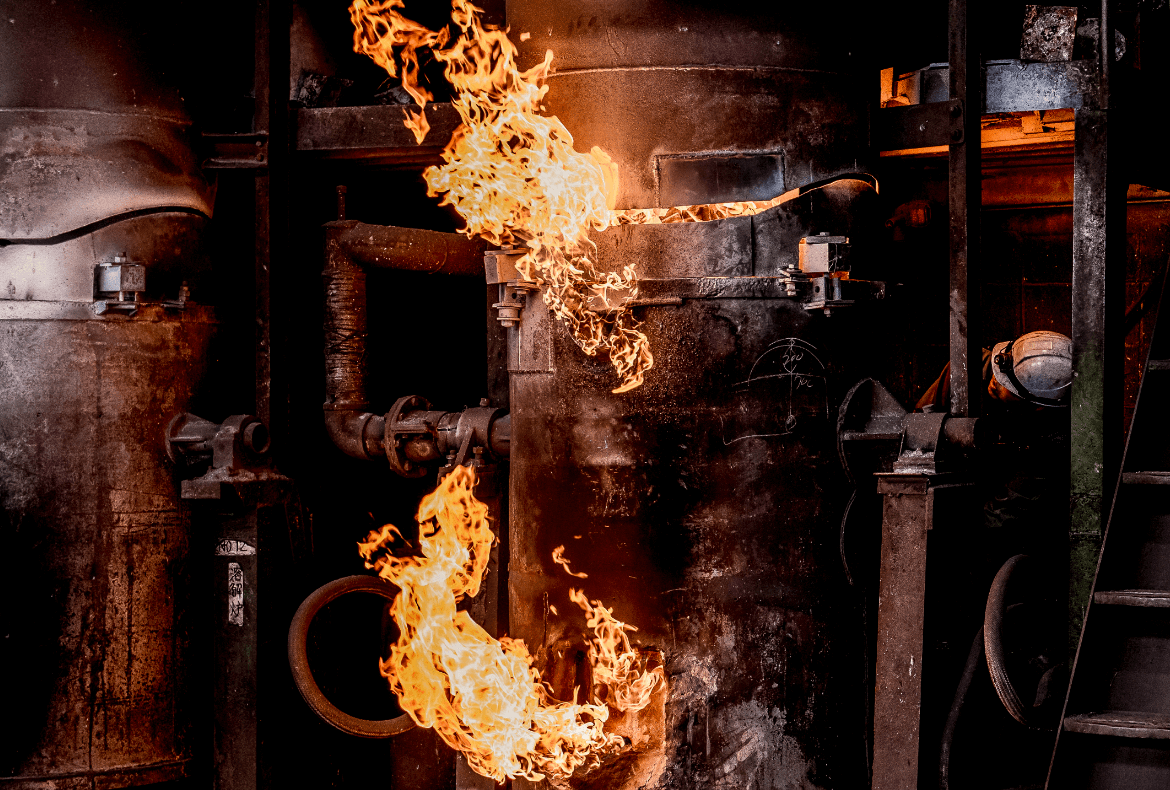

We specialize in highly difficult castings with multiple cores using the technology we have cultivated as a top manufacturer of various electric furnaces.

VIEW MORE

Procurement information

We are looking for a wide range of suppliers to cooperate with us in procuring materials, parts, equipment, and various services.

VIEW MORE

superheated steam technology

Introducing superheated steam technology, which has high energy density and thermal efficiency and is used in many industrial processes.

VIEW MORE

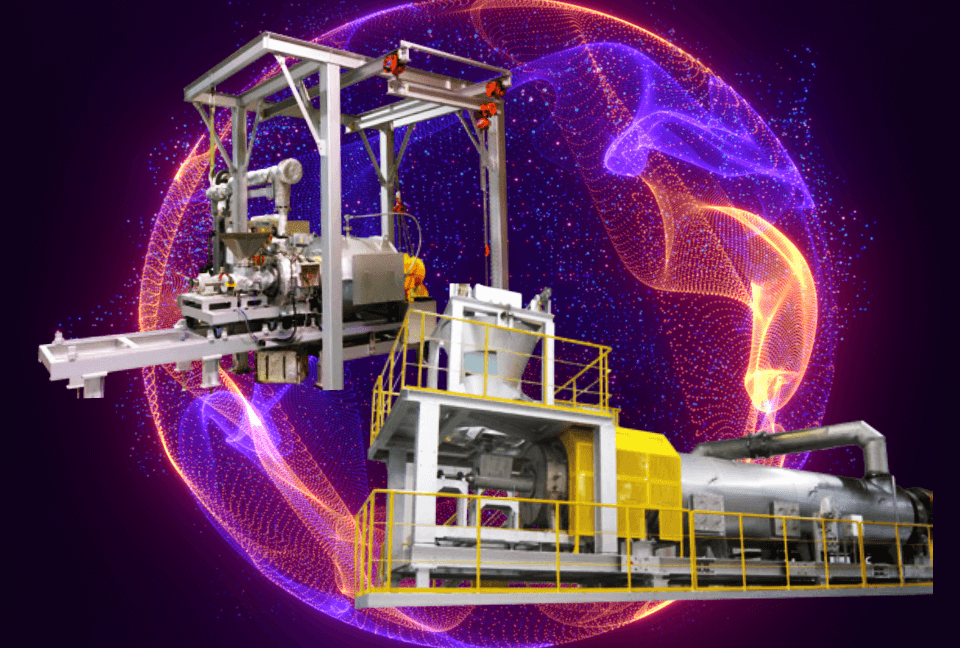

Contract manufacturing

This is a contract manufacturing business that utilizes our own manufacturing and processing equipment such as electric furnaces and rotary kilns.

VIEW MORECONTACT

To Tanabe, world-recognized thermal technology

Please feel free to contact us.